Pool distribution is a form of shipping that allows companies to ship their products along with other orders in a single truck. This strategy is similar to less-than-truckload (LTL); however, you would be pooling multiple shipments of your products rather than sharing the load with other brands.

For anyone looking to reduce costs and improve transit times, the pool distribution model is one of the most practical solutions.

What is Less-than-truckload (LTL) shipping?

LTL is a shipping option that allows companies to pay only for the portion of the trailer they use rather than the entire truck. The remaining space will be filled with goods from other companies heading to the same area.

Pool Distribution vs. Pool Consolidation?

Pool distribution allows you to “pool” your shipment together with other loads that are being delivered to multiple destinations within the same region.

Shipments that would usually be shipped through LTL shipping can be pooled together or consolidated onto a full trailer. Next, they are delivered to a distribution center offloaded, and sent to their final delivery.

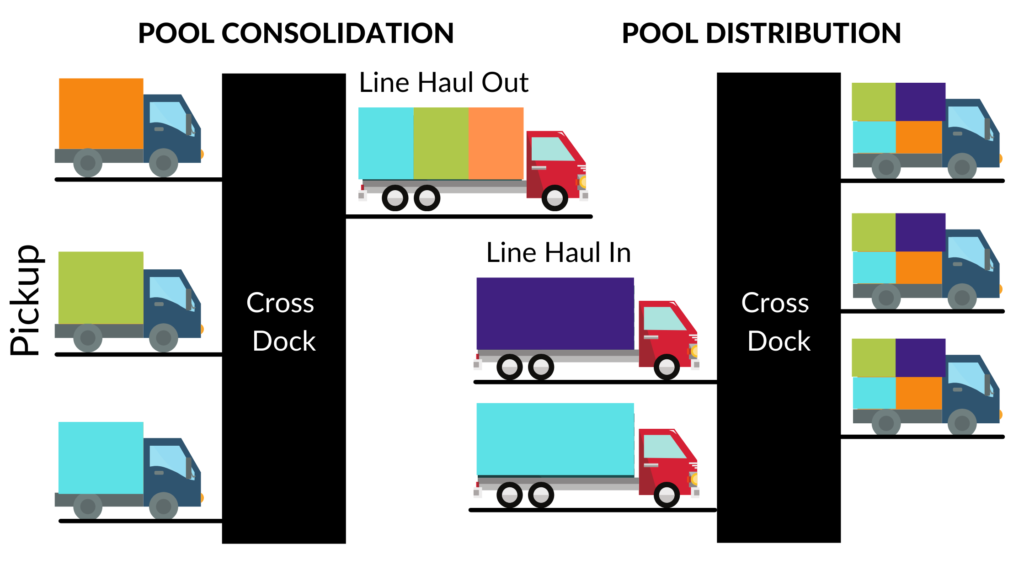

You can utilize pool distribution at both ends of the shipping lane — the origin and destination. The beginning of the trip is called pool consolidation. Whereas pool distribution refers to the end portion, when the shipment is removed from the truck, scanned, and delivered to its final destination.

How Does Pool Distribution Work?

Usually, pool distribution involves consolidating multiple shipments from a single shipper at one point of origin — typically the shipper’s distribution center. The load as a whole will be going toward a specific geographic region, with multiple delivery points within that region for individual shipments.

Shipments are consolidated and loaded onto a truck to make maximum usage of the space. Next, it goes to a pool point facility (aka a regional terminal) or distribution center, instead of directly to the final destination.

What Is A Pool Point In The Pool Distribution Process?

A pool point is the location where goods are further sorted, consolidated, and shipped to other destinations by the shipper’s 3PL partner. At the pool point, the pool shipment will be offloaded, scanned, and organized by where the freight is headed. Your shipments are then reloaded onto smaller, local delivery trucks or vans for their final mile delivery.

In some cases, a company may not have enough product to make pool distribution a good option. Instead, the pool might share a truckload cost with another pool from a different company. When this occurs, the truck will stop at both distribution points to load in the shipment and then go to a single final delivery point, meaning the two pools are being shipped to the same retailer.

Pool distribution can often offer significant cost savings to traditional LTL shipping. Benefits include significantly reduced shipping times, less handling of your products, keeping them safer, and visibility to track your shipment throughout the entire journey.

A pool distribution strategy is more common on a smaller scale; however, larger companies can benefit from this shipping method. The right partners will have a set of network points and distribution centers to unload trucks and sort items for distribution.

Using an experienced partner for pool distribution is valuable because they will already have the systems and right personnel in place, particularly for shipments that require special vehicles such as smaller vans or trailers with lift gates. An experienced partner will also have the right floor personnel needed to receive deliveries with the necessary know-how to use any specialized equipment.

When To Use Pool Distribution?

You may have already used pool distribution in some form. For example, if a retailer asked you to consolidate your orders onto pallets and ship them via LTL instead of parcel delivery.

Companies with a high frequency of consistent, LTL-size shipments are best suited to use a pool distribution strategy. It is dependent on the size and the circumstances of your orders. Pool distribution may make sense as part of your regional small parcel delivery strategy.

While smaller companies may be better suited for pool distribution, you still need a certain level of volume for it to bring value to your business. To benefit from the value that pool distribution brings, companies need to have enough sales volume and shipments to a specific geographic region. If a company doesn’t have enough product to fill a truck, it is most likely better suited for LTL shipping than pooling. Working with an experienced third-party logistics provider is crucial because they can provide an established carrier network to help identify the best strategy to bring value to your supply chain. Particularly for companies lacking the infrastructure or the systems to coordinate pooling.

What is Pool Consolidation?

Pool consolidation is part of the pool distribution process at the shipping lane’s beginning. With consolidation, multiple vendor shipments are consolidated onto a single truckload to a distribution center. The lane’s pool distribution portion occurs as the shipments are separated and sent to their final destination.

Other times, pool consolidation is not paired with pool distribution. In these cases, the vendors that share the truckload are all going to the same retailer or other location, creating no need for distribution at the end.

Companies typically use third-party logistics providers to handle their shipping as there is a lot of coordination that goes into pool consolidation. The planning process considers many factors, including delivery dates, shipping schedules, and truck availability.

Pooling saves time at both the beginning and the end of a shipment’s journey. You can load your entire shipment into a single truck rather than in pieces, and on the other end, it only needs to be unloaded once. This means fewer receiving doors are required, and fewer workers are required to unload the shipment.

The Benefits Of Pool Distribution in Supply Chain Management

- Reduced Shipping Costs: Pool distribution is typically more efficient than other shipping options as it removes the need for multiple legs on the journey. With shipping, the most costly miles for a truck are the first and last few miles.

- Straightforward: Usually, pool distribution cost is based on just weight and miles, meaning it does not require complex formulas and is a more straightforward way to calculate the costs.

- Supply Chain Visibility: Pool distribution makes it easy to track your shipment as it will be making fewer stops.

- Speed: Pool distribution is typically faster as your shipment will be making fewer stops.

- Lower Carbon Footprint: By placing fewer trucks on the road, you are doing your part to reduce your companies’ carbon footprint.

Why Pool Distribution Might Not Be Right For Your Business

- Requires Change: Some companies may not be willing to change processes, schedules, or volumes to make pool distribution work.

- Filling the trucks: You want to make sure you can fill the trucks with your pooled shipment consistently. Otherwise, pool distribution will have minimal value as part of your supply chain.

- Right Partner: You want to ensure your 3PL/ 4PL partner has an established network in the regions you wish to send your pool shipments.

- Product Pooling: Ensure the products you pool together make sense to be on the same truck. Depending on your products, some items may require special handling or shouldn’t be pooled together pending on your products’ nature.

Implementing pool distribution will require a lot of initial work on your end, but once you have systems in place with the right shipping partner, it will be worthwhile for your company.